Membranes represent an indispensable part of membrane processes and they are often considered a decisive element in the optimization of their quality and performance. A membrane is basically a complex and highly effective multifunctional barrier, separating two media and facilitating or hindering transport of various substances in a very selective manner. Membranes work in many applications – production of drinking water, energy transformation, regeneration of tissues, wrapping technology, separations in the food-processing industry, production in chemical, automotive and electronic industries etc. Besides their traditional separation function, there are requirements for special types of use of membranes in catalyzed reactions in membrane reactors, in phase contact (membrane contractors) etc. In various areas, membranes are required with specific properties (hydrophobicity, oleophobicity, haemocompatibility), functionalized membranes with specific ligands including ion-exchange membranes, membranes with higher resistance against solvents and various detergents, resistant against high temperatures or extreme pH, with higher selectivity without any performance drop and usable in standard basic modules etc. Answers to all these different requirements are to be sought in material security of preparation and production of membranes (polymers, metals, ceramics or their hybrid structures), as well as technological methods of preparation of thin layers.

The biggest portion of used membranes has been produced from organic polymeric compounds. One of their advantages is the variability of preparation methods, which allows creating needed physical structures of membranes both in solid phase and in solution. The first materials of this type were cellulose derivates, today replaced by synthetic polymers in most applications. Membranes from suitable thermoplastic materials are used in the pressure membrane operations of micro-filtration and ultra-filtration. Membranes for reverse osmosis must be produced from better quality materials. The target structures of functionalized polymers and their composite structures are material prepared for electrochemical processes and also prospective materials for newly developed membrane technologies. The second type of materials, with a constantly growing field of utilization, is inorganic cemented ceramics, intended primarily for pressure filtration operations. With the exception of palladium, metal membranes are used very rarely so far.

With respect to their function, synthetic membranes are often compared to biological membranes, although they are only a raw replica of the latter. If synthetic membranes are to be more effective, “intelligent”, multifunctional, biocompatible, chemically and thermally resistant, resistant against so-called bio-fouling, processible into modules and weldable using available techniques, i.e. if they are to be as close to their ideal state in processing and use as possible, it is necessary to resolve the properties of membrane materials on both nano and molecular levels, thus improving substantially the global approach towards the membrane engineering.

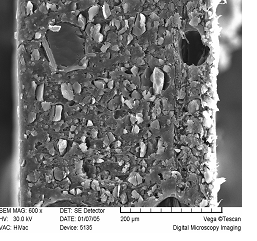

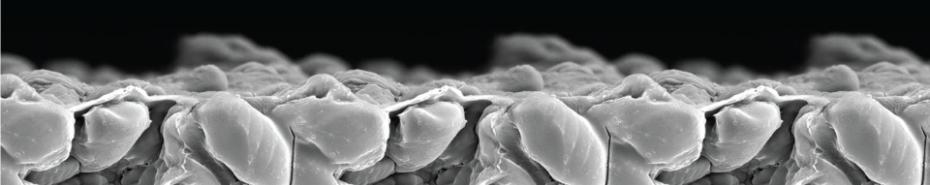

Structure of heterogeneous ion-exchange membrane

Ion-exchange membranes

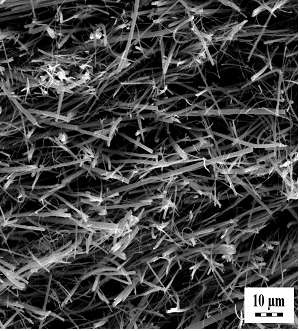

Micro-filtration fibre membranes

EUROPEAN UNION

EUROPEAN UNION