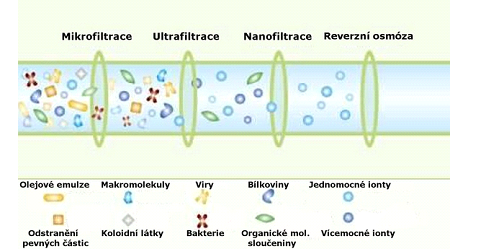

The name of the pressure membrane processes usually refers to four types of separation techniques: micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) and reverse osmosis (RO). Their common feature is the use of a semi-permeable membrane as the separation element and the pressure gradient as the driving force for transportation through the membrane. Their differences are in the extent of the applied pressure gradients, properties of the membrane and prevailing transportation mechanism. The pressure membrane processes are used to concentrate or refine diluted solutions and dispersions. The size of separated particles or molecules and chemical properties of the solvent are critical in the selection of the appropriate membrane type. The principles of the pressure membrane processes are shown in Figure 1.

Fig 1: Scheme of micro-filtration, ultra-filtration, nano-filtration and reverse osmosis

Due to the influence of the driving force, i.e. the pressure difference above and below the membrane, molecules of the solvent or low-molecular-weight substance pass through the membrane, while bigger molecules or particles are caught by the membrane. From MF through UF and NF to RO, the size of the separated particles (or molecules) gets smaller, as well as the size of the membrane pores. This also leads to an increase in the membrane resistance against mass transfer, and to achieve the same intensity of the permeate flow, it is necessary to apply higher pressure. However, there are no sharp boundaries between individual pressure membrane processes.

MICRO-FILTRATION

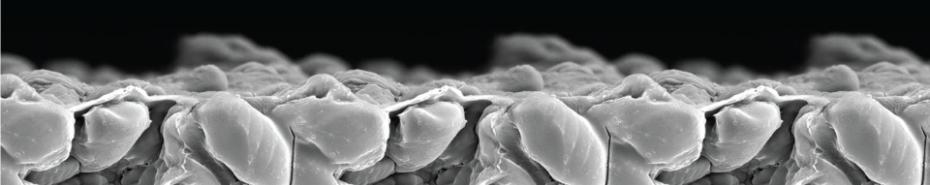

Membranes: (a)symmetric porous

Thickness: 10-150 µm

Pore size: 0.1-10 µm

Driving force: pressure gradient (< 4 Bars)

Separation principle: sieve mechanism

Membrane material: polymeric, ceramic

Application:

- removal of bacteria and yeasts from beer, wine and milk

- purification and sterilization of juices

- water treatment in production of purified water

- separation of fine crystals in pharmaceutical industry

- thickening of oil from oil emulsions

- process preceding UF and RO

ULTRA-FILTRATION

Membranes: asymmetric porous

Thickness: 150 m

Pore size: 1-100 nm

Driving force: pressure gradient (1–10 Bars)

Separation principle: sieve mechanism

Membrane material: polymer (polysulfone, polyacrylonitrile), ceramics

Application: - processing of oil emulsion

- retrieving electrophoretic paints from rinse water

- processing of waste water from textile and paper industries

- thickening of latex emulsions

- thickening of proteins and processing of whey

- haemodialysis

- process preceding RO

NANO-FILTRATION

Membranes: composite

Thickness: carries approx. 150 m, active layer approx. 1 m

Pore size: 2 nm

Driving force: pressure gradients (10-25 Bars)

Separation principle: solution–diffusion

Membrane material: polyamides

Application: - water softening

- elimination of nitrate ions from drinking water

- desalination of products and semi-products in chemical industry

- purification of waste water from galvanizing shops, textile and paper industries

REVERSE OSMOSIS

Membranes: asymmetric or composite

Thickness: carrier approx. 150 m, active layer approx. 1 m

Pore size: 2 nm

Driving force: pressure gradient (15-80 Bars)

Separation principle: solution–diffusion

Membrane material: cellulose acetates, polyamides

Application: - desalination of sea and brackish water in production of drinking water

- production of purified water for electrical and pharmaceutical industries

- purification of waste water from galvanizing shops, textile and paper industries

- rinsing of surgical and laboratory tools before sterilization

- dialysis

- feeding of high-pressure boilers

Výrazy ve schématech (Fig. 1):

Bakterie = Bacteria

Bílkoviny = Proteins

Jednomocné ionty = Univalent ions

Koloidní látky = Colloid substances

Makromolekuly = Macro-molecules

Mikrofiltrace = Micro-filtration

Nanofiltrace = Nano-filtration

Odstranění pevných částic = Removal of solid particles

Olejové emulze = Oil emulsions

Organické mol. sloučeniny = Organic molecular compounds

Reverzní osmóza = Reverse osmosis

Ultrafiltrace = Ultra-filtration

Vícemocné ionty = Multivalent ions

Viry = Viruses

EUROPEAN UNION

EUROPEAN UNION